Running Specific Prosthetic Foot

Motivation

Running has different biomechanics than walking (i.e. more push off energy generated by the ankle than during walking) and in order to replicate a biological ankle during running, running specific prostheses (RSPs) have been developed. RSPs are designed to replicate the spring like behavior of the lower limbs while running and are shaped as curved cantilever beams with a high capacity to store and return energy. Currently RSPs are categorized by shape and stiffness category (which can vary from manufacturer to manufacturer), and the design and fitting of RSPs has been mainly focused around a trial and error approach. Prosthetists tend to prescribe RSPs based on user weight and activity level as opposed to specific end point mechanics (i.e. overall stiffness and displacement of the toe of the prosthetic foot) that can best meet the user’s needs. It is possible to optimize the shape of an RSP to produce specific endpoint mechanics using finite element analysis (FEA), but it is a complex problem to solve. We have been able to simplify the problem by reducing a complex set of endpoint mechanics into three metrics: angular, vertical, and horizontal displacement of the toe of the prosthetic which we then used to design RSPs from a given set of endpoint mechanics.

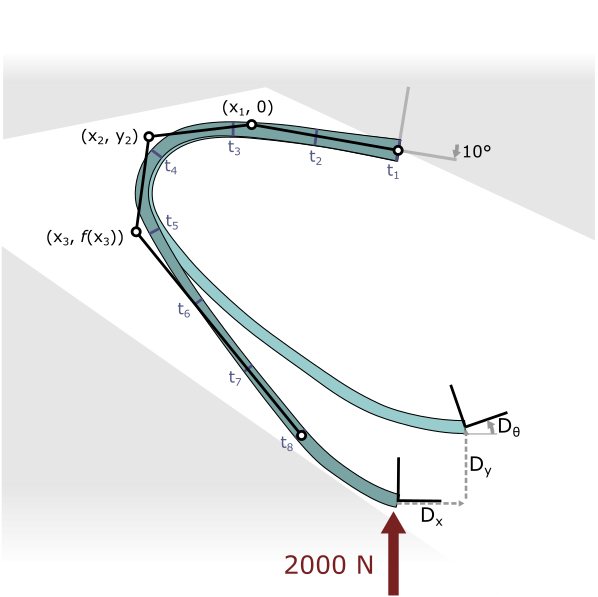

The RSP shape was defined by a non-uniform rational B-Spline, with four degrees of freedom in the control points, and two internal knots (not illustrated) allowed to vary. Eight locations along the curve describe the thickness. The toe geometry is fixed to preserve rolling behavior across feet. For the optimization the foot is pitched forward 10°, and the nominal vertical force of 2000 N is applied to the toe. Dx, Dy, Dθ are the horizontal, vertical, and angular deflections of the toe, respectively.

Approach

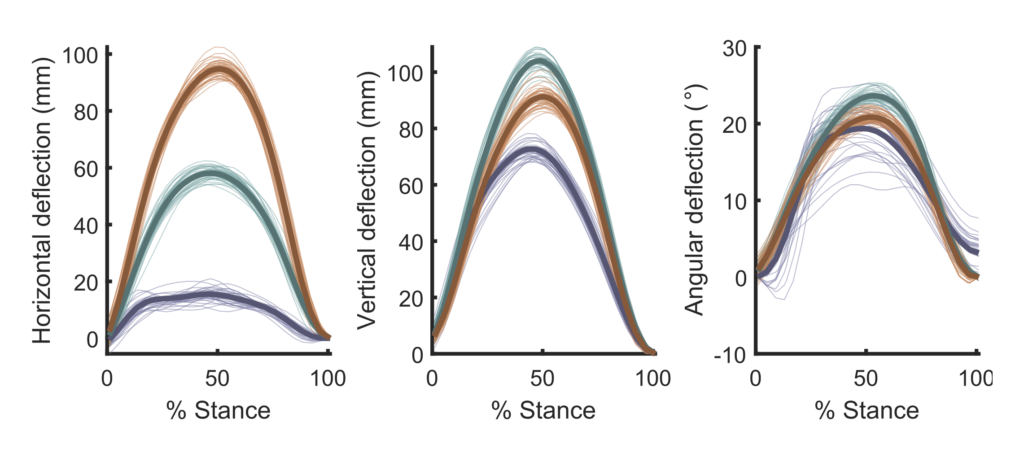

We developed a custom, spline-based optimization that optimized RSP shape based on a given set of end point mechanics. We validated our approach by designing and characterizing three different RSPs with different horizontal deflections, but the same vertical and angular deflections (left). The RSPs were manufactured from carbon fiber and their endpoint mechanics were characterized by applying a 2000N vertical load to the toe. The three prototypes performed as expected and exhibited the desired endpoint mechanics.

We additionally completed a biomechanical analysis of a single subject who ran with the three different RSPs. Using motion capture technology and an instrumented treadmill we were able to document and understand how the RSPs behaved when worn by a human. The RSPs deflected as expected although the angular and vertical deflections were not constant across the feet (below). These differences are partially due to different end point forces being applied to the RSPs during human testing as opposed to the idealized force applied during the optimization. We will continue to test these RSPs on other athletes with below and above knee amputations with the goal of building better mapping between RSP mechanics and associated biomechanics and, ultimately, between biomechanics and athlete performance.

Contributors: Max Shepherd, Hannah Frame